Why Troubleshooting is Critical

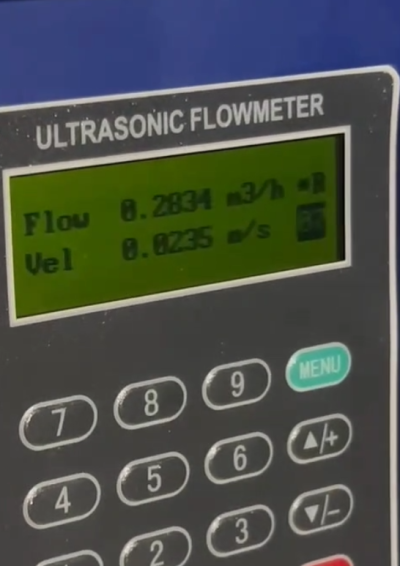

Even with precise installation, the OUF-W Series Ultrasonic Flowmeter may encounter issues like signal loss, erratic readings, or error codes. Proactive troubleshooting ensures long-term accuracy and minimizes downtime. This guide addresses common problems, from diagnosing error codes to resolving electromagnetic interference (EMI), empowering users to maintain peak performance.

Step 1: Diagnosing Error Codes (Menu M08)

The OUF-W displays system statuses and errors in Menu M08. Key codes include:

• R: Normal operation.

• E01: Transducer fault (check wiring or codes).

• E05: Empty pipe (signal strength < threshold set in M29).

• E10: Parameter error (re-validate M11–M14).

Action Steps:

1. Navigate to M08 to view the error code.

2. Cross-reference the code with the manual’s appendix.

3. Reset defaults (M37) if unresolved, then reconfigure parameters.

Step 2: Resolving Signal Strength Issues (Menu M90)

Poor signal strength (M90 < 60) or low quality (Q < 60) often stems from:

• Misaligned Transducers: Recheck installation distance (M25) and alignment (Articles 5–7).

• Poor Couplant Application: Clean and reapply couplant evenly.

• Pipe Scaling: Use insertion transducers or clean the pipe interior.

Step 3: Correcting Transmission Time Ratio (Menu M91)

A ratio outside 97–103% in M91 indicates:

• Incorrect Pipe Parameters: Re-measure outer diameter (M11) and wall thickness (M12).

• Transducer Distance Error: Verify physical spacing matches M25.

• Fluid Sound Velocity Mismatch: Compare M92 to reference values (e.g., 1480 m/s for water).

Step 4: Mitigating EMI Interference

Symptoms: Erratic readings, fluctuating totals.

Solutions:

• Grounding: Ensure shield wires are grounded (resistance <1Ω).

• Cable Separation: Keep signal cables 30cm away from power lines.

• Isolated Power Supply: Use a UPS or filter to stabilize input power.

Step 5: Calibrating Flow Readings

1. Zero Calibration (M42):

o Stop flow completely.

o Navigate to M42 and press ENT to reset zero.

2. Span Calibration (M45):

o Compare OUF-W readings with a master meter.

o Adjust M45 (scale factor) until deviations are <±1%.

Advanced Diagnostics

• M92 (Fluid Sound Velocity): Deviations >5% from expected values suggest incorrect liquid type (M20) or sensor faults.

• M94 (Reynolds Number): Confirm turbulent/laminar flow profiles match system design.

Common Pitfalls

• Ignoring Pipe Fill: Ensure the pipe is 100% full—partial fill triggers false “empty pipe” errors.

• Overlooking Temperature Effects: High-temperature fluids require HT-rated transducers and couplant.

• Skipping Post-Fix Checks: Always revalidate signals (M90/M91) after adjustments.

Download Kaifeng Oasis’s Troubleshooting Toolkit—includes error code decoders, calibration templates, and EMI mitigation checklists. For urgent issues, contact our 24/7 technical support team via live chat or phone!

Next in the Series

In Article 10: Advanced Features & Maintenance for OUF-W Flowmeters, we’ll explore data logging, firmware updates, and predictive maintenance strategies.

Please contact us for free quotation by form below. We promise the quickest response within 24 hours: