Why Configuration Matters

Proper configuration of the OUF-W Series Ultrasonic Flowmeter ensures accurate readings, seamless integration with control systems, and long-term reliability. This guide walks through critical parameter setups, alarm configurations, and communication protocols, empowering users to optimize performance for diverse applications.

Step 1: Basic Parameter Setup

Access the OUF-W menu by pressing MENU followed by the two-digit menu number. Key parameters include:

|

Menu |

Parameter |

Input Guidelines |

|

M11 |

Pipe Outer Diameter |

Measure with calipers (0–18,000mm). |

|

M12 |

Pipe Wall Thickness |

Use an ultrasonic thickness gauge. |

|

M14 |

Pipe Material |

Select steel, PVC, etc. (affects sound velocity). |

|

M20 |

Liquid Type |

Choose water, oil, or custom fluids. |

|

M23 |

Transducer Type |

Match codes (e.g., TS-2 for clamp-on). |

|

M26 |

Cure Parameters |

Save settings to flash memory. |

Pro Tip:

Always cure parameters (M26) after configuration to prevent data loss during power cycles.

Step 2: Unit & Alarm Configuration

Units (M30–M33)

• M30: Metric (m³/h) or British (GPM).

• M31: Flow rate unit (e.g., L/s, m³/h).

• M32: Totalizer unit (e.g., kL, MG).

• M33: Totalizer multiplier (0.001–10,000).

Alarms (M73–M79)

• M73/M74: Low/High flow rate triggers for Alarm 1.

• M75/M76: Low/High flow rate triggers for Alarm 2.

• M78/M79: Assign alarms to relays (OCT) or buzzers.

Step 3: Calibration & Validation

1. Zero Calibration (M42):

o Ensure no flow in the pipe.

o Navigate to M42 and press ENT to reset zero point.

2. Flow Rate Calibration (M45):

o Compare OUF-W readings with a master meter.

o Adjust M45 (scale factor) if deviations exceed ±1%.

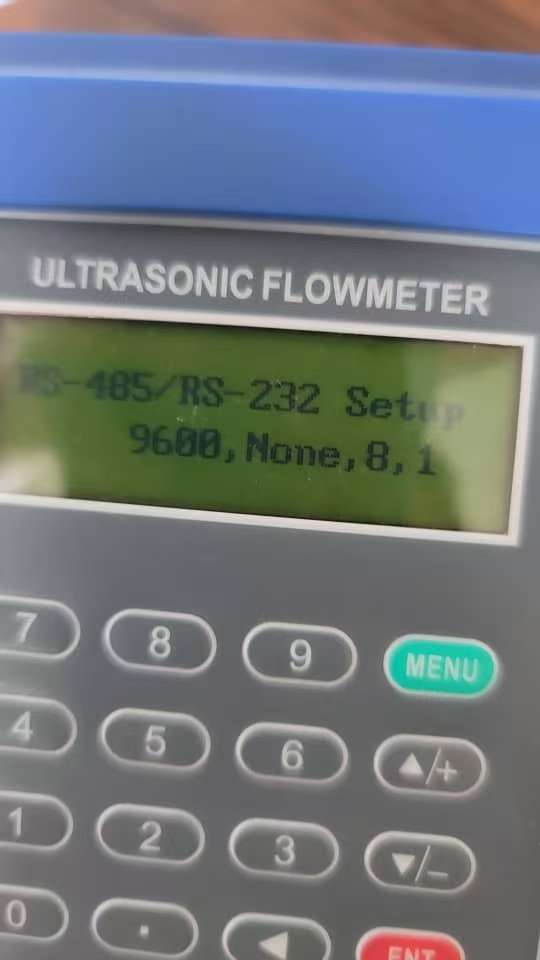

Step 4: MODBUS Communication Setup

1. RS485 Configuration (M62):

o Set baud rate (9600–115,200), parity (None/Even/Odd), and stop bits.

2. Protocol Selection (M63):

o Choose MODBUS RTU (industrial) or ASCII (legacy systems).

3. Device ID (M46):

o Assign unique addresses (1–247) for multi-device networks.

Testing Communication:

Use a MODBUS master (e.g., PLC or software) to read registers:

• Flow Rate: Register 40001 (Float32).

• Totalizer: Register 40003 (Float32).

Common Pitfalls & Solutions

• Mismatched Transducer Codes: Recheck M23 and transducer labels.

• EMI Interference: Ground shield wires (resistance <1Ω) and separate power/signal cables.

• Unstable Readings: Increase damping factor (M40) to 5–10 seconds.

Get in touch with our team to get access to our installation videos and menu setting techniques tutorials!

Next in the Series

In Article 9: Troubleshooting OUF-W Ultrasonic Flowmeters, we’ll tackle error codes, signal loss, and advanced diagnostic techniques.

Please contact us for free quotation by form below. We promise the quickest response within 24 hours: