Unlocking the Full Potential of OUF-W Flowmeters

The OUF-W Series Ultrasonic Flowmeters by Kaifeng Oasis offer advanced functionalities beyond basic flow measurement, including heat calculation, data logging, and predictive maintenance. This guide explores these features, ensuring you maximize ROI and system longevity in industrial or municipal applications.

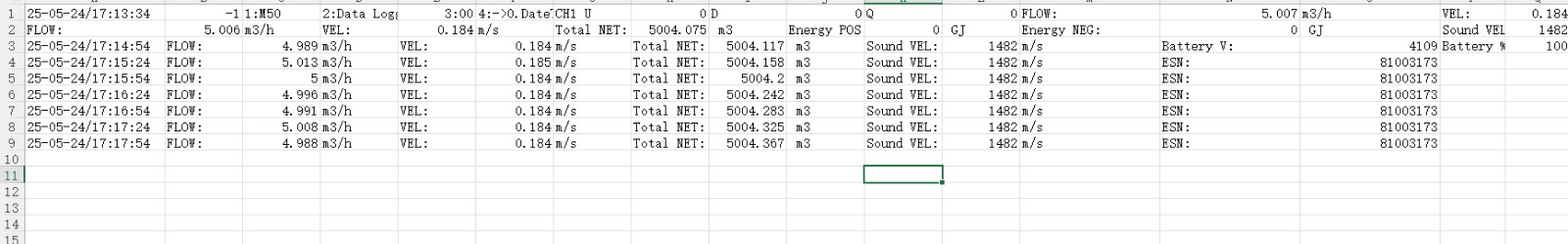

1. Data Logging & Analysis (Menu M50)

The OUF-W’s built-in data logger stores up to 64 days of historical data, including:

• Flow rates (M00/M01).

• Totalized values (M02/M03).

• Temperatures (M06) and alarms (M08).

Setup:

1. Navigate to M50 and select “YES” to enable logging.

2. Choose parameters (e.g., flow rate, energy totals).

3. Set logging intervals (1s–24h) in M51.

4. Direct data to RS485 (M52) or internal storage.

2. Heat Measurement & Energy Calculation

For HVAC or district heating systems, pair flow transducers with PT100 sensors:

1. Connect Sensors: Wire PT100 probes to terminals 51-56 (T1/T2).

2. Configure Menus:

o M85: Select temperature sources (default: T1/T2).

o M86: Set specific heat (e.g., 4.187 kJ/kg°C for water).

o M87: Enable energy totalizer (GJ, kWh, BTU).

3. MODBUS Integration & Custom Protocols

The OUF-W supports industrial automation via:

• MODBUS RTU/ASCII (M63): Assign device IDs (M46) and baud rates (M62).

• Analog Outputs (M55–M57): Map 4-20mA signals to flow rate or temperature.

4. Predictive Maintenance Strategies

1. Signal Health Monitoring:

o Check M90 (signal strength >75) and M91 (97–103% ratio) monthly.

2. Battery Replacement:

o The internal RTC battery (CR2032) lasts 5+ years. Replace it during downtime to preserve logs.

3. Firmware Updates:

o Download updates from Kaifeng Oasis’s portal and upload via RS485.

5. Advanced Diagnostics & Tools

• M+5 (Scientific Calculator): Compute fluid density or Reynolds numbers on-site.

• M48 (Linearity Correction): Input calibration data to correct non-linearities.

• M96 (Circular Display): Cycle through key parameters (M00–M95) automatically.

Optimize your OUF-W’s performance! Schedule a consultation with our engineers to unlock hidden capabilities!

Conclusion

From energy audits to predictive maintenance, the OUF-W Series empowers industries to achieve operational excellence. By leveraging advanced features like MODBUS, data logging, and heat measurement, users gain actionable insights while minimizing downtime.

Please contact us for free quotation by form below. We promise the quickest response within 24 hours: