Why Insertion Transducers? Precision Meets Durability

Insertion transducers for the OUF-W Series are ideal for permanent installations on pipes ≥DN50, offering high accuracy even in scaled or turbulent flow conditions. Unlike clamp-on models, they require drilling into the pipe but provide reliable performance in harsh environments (up to 160°C and 1.6MPa pressure). This guide details pressure-safe drilling, alignment, and signal optimization for seamless integration.

Tools and Safety Gear

• Ball Valve Kit: Enables drilling under pressure (included upon request).

• Open-Hole Tool: Drill bit, rod, and sealing cover for creating a pilot hole.

• Pipe Hoop or Welding Equipment: For fixing the ball valve base (non-weldable pipes require hoops).

• Ultrasonic Thickness Gauge: Measure pipe wall thickness (critical for insertion depth).

• Torque Wrench: Tighten locknuts to 20 Nm.

• PPE: Safety goggles, gloves, and flame-resistant clothing for drilling.

Step 1: Selecting Installation Method

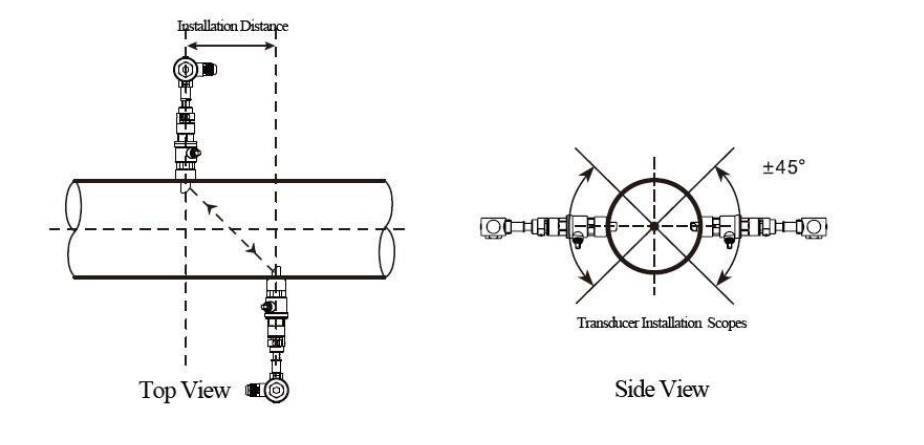

Choose between V-method (DN50–300) or Z-method (DN50–6000) based on space and pipe size:

• V-Method: Transducers mounted horizontally on opposite sides, parallel to flow.

• Z-Method: Transducers installed vertically on the same axial plane (recommended for large pipes).

Pro Tip:

For restricted spaces (e.g., underground ducts), use parallel insertion (TP-1) with a 300–500mm spacing.

Step 2: Ball Valve Base Installation

Welding (Steel Pipes):

1. Clean the pipe surface around the installation point.

2. Weld the ball valve base, ensuring the center aligns with the transducer position.

3. Remove PTFE gaskets before welding to avoid damage.

Pipe Hoop (Non-Weldable Pipes):

1. Attach a custom hoop around the pipe, centered on the installation point.

2. Compress rubber seals evenly to prevent leaks.

Common Mistake:

Skipping post-weld inspections for air pockets or misalignment can cause leaks.

Step 3: Drilling Under Pressure

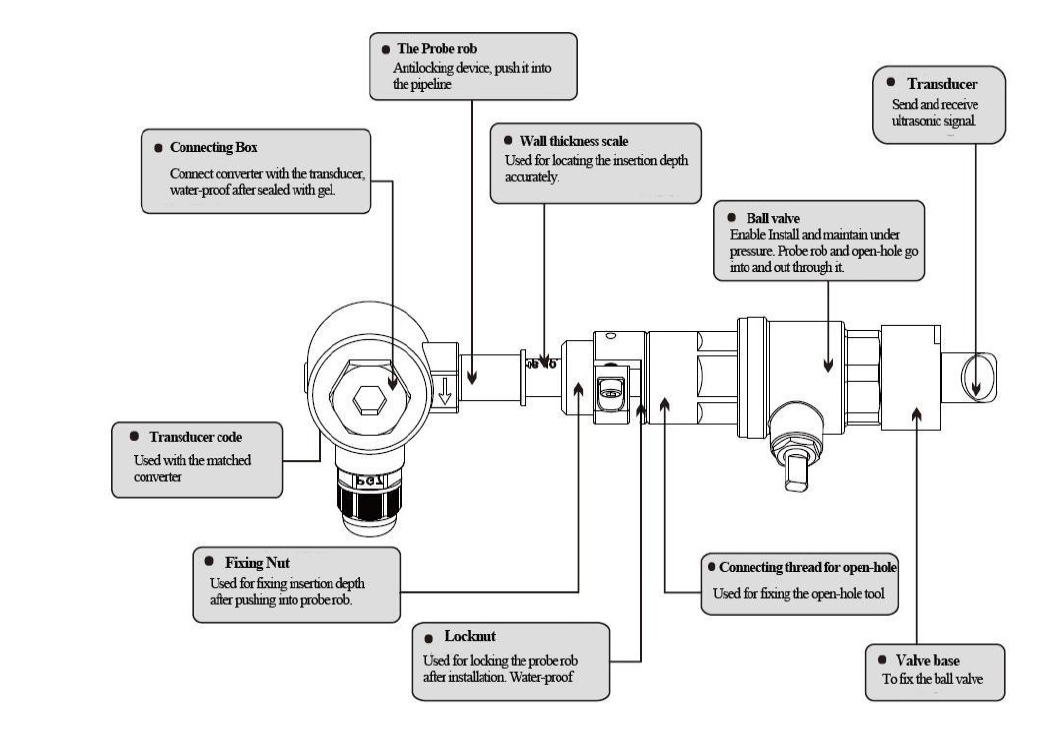

1. Attach Ball Valve: Screw the valve into the base and open it fully.

2. Insert Open-Hole Tool:

o Lock the drill rod into the valve.

o Start drilling slowly, increasing speed gradually.

3. Retract and Close Valve:

o Withdraw the tool and close the valve to isolate pressure.

o Remove the drill bit and attach the seal cover.

Step 4: Transducer Installation & Alignment

1. Adjust Insertion Depth:o Set the depth scale to 1/3 of the pipe’s inner diameter (e.g., 33mm for DN100 pipe).

o Push the transducer rod fully into the pipe.

2. Align Direction Arrows:

o Ensure arrows on upstream/downstream transducers point opposite to each other and parallel to flow.

3. Secure with Locknuts:

o Tighten locknuts to 20 Nm while holding the transducer in place.

Pro Tip:

Use a laser level for large pipes (DN500+) to ensure transducers lie on the same axial plane.

Step 5: Signal Verification & Troubleshooting

1. Signal Strength (M90):

o Target Q > 60 and signal strength > 75.0 for reliable readings.

2. Transmission Time Ratio (M91):

o A 97–103% ratio confirms correct parameters and alignment.

3. Adjustments:

o Weak Signals: Recheck insertion depth or realign arrows.

o Fluctuating Readings: Ensure the pipe is full and free of air bubbles.

Common Pitfalls

• Ignoring Pipe Material: Avoid using TC-1 on non-metallic pipes without stabilizing brackets.

• Over-Tightening: Damages transducer rods; use a torque wrench.

• EMI Interference: Keep signal cables 30cm away from power lines.

Master pressure-safe drilling! Get in touch with our engineers to get one-on-one guidance on the installation of insertion transducers!

Next in the Series

In Article 7: Inline Transducer Installation for OUF-W Flowmeters, we’ll cover flange welding, pipeline alignment, and leak-proof sealing for high-pressure systems.

Please contact us for free quotation by form below. We promise the quickest response within 24 hours: